Tire ASRS warehouse is an advanced warehouse management system, which can effectively manage and store a large number of tire products. In the tire manufacturing and distribution industry, accurate in-and-out processes are critical to improving efficiency and meeting customer needs. This paper will introduce the flow of the tire warehouse in and out, in order to show its efficient inventory management ability.

The first step: warehousing process

1. Tire arrival acceptance: tire products arrive at the warehouse, acceptance work. Check the quantity, model, specification and quality of the goods, and check them against the order or delivery to ensure that they are correct.

2. Data entry: Input relevant information of incoming goods into the warehouse management system, including important information such as tire model, quantity and production date. The system assigns a unique identification number to each tire for subsequent tracking and management.

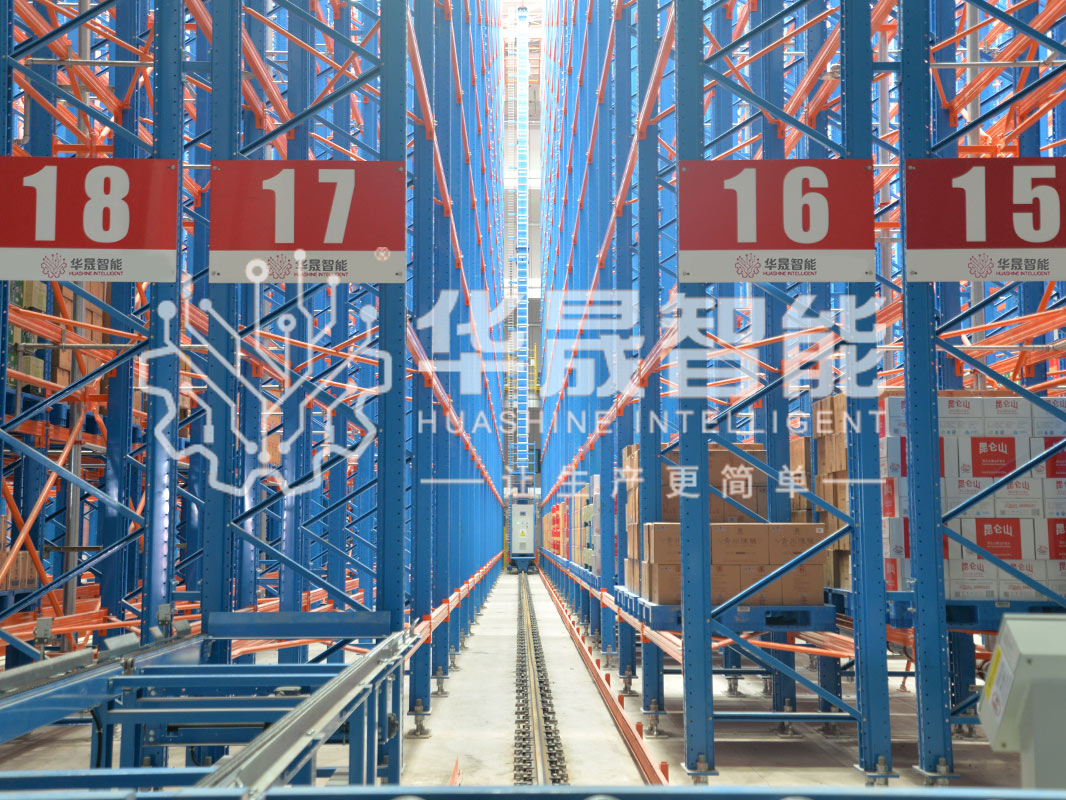

3. Goods shelves: Put the tires on shelves according to the specified storage position. According to the guidelines of the warehouse management system, the tires are placed on the corresponding shelves or storage Spaces to ensure that the inventory is neat and traceable.

The second Step: Outbound process

1. Order reception: According to customer orders or sales needs, the warehouse management system generates outbound tasks. The task contains details such as the number of tires required, the model and the delivery date.

2. Goods selection: The warehouse staff will find the corresponding tires in the warehouse according to the outbound tasks. Use the picking tools or equipment provided by the warehouse management system to ensure accurate picking of the required tires.

3. Packaging and marking: the selected tires will be packaged to ensure safety and protection during transportation. Mark the packaging with relevant information such as customer name, order number, etc.

4. Delivery preparation: The tire products are ready for delivery, including loading into the transport vehicle or ready to be delivered to the logistics company. Ensure that the outgoing records and warehouse management system are updated to reflect actual stock changes.

The third Step: Inventory management

1. Inventory monitoring: real-time monitoring and tracking of inventory through the warehouse management system. Timely update the tire storage, storage records, inventory, storage location information, etc., to ensure the accuracy of inventory and visual management.

2. Inventory adjustment: According to the actual situation, the inventory adjustment and inventory. Check the accuracy of inventory data regularly, carry out inventory counting and adjustment to ensure that the inventory quantity is in line with the actual situation.

3. Inventory optimization: Optimize inventory management strategies by analyzing inventory data and sales trends. Reduce inventory costs and risks while ensuring inventory turnover and meeting customer needs.

The in-and-out process of tire warehouse is an efficient inventory management process. Accurate incoming and outgoing processes can ensure the accuracy and traceability of inventory and improve the efficiency of warehouse work. Through the application of warehouse ASRS management system and the formulation of inventory optimization strategy, the tire warehouse can achieve a higher level of inventory management and improve the competitiveness of tire manufacturing and distribution industry.